Elastomeric Materials

The Department of Plastics Engineering provides instruction about and performs research on thermoplastic and thermoset elastomers. Since thermoset elastomers, including thermoset rubber, require specialized equipment, the Department created a laboratory for thermoset elastomers.

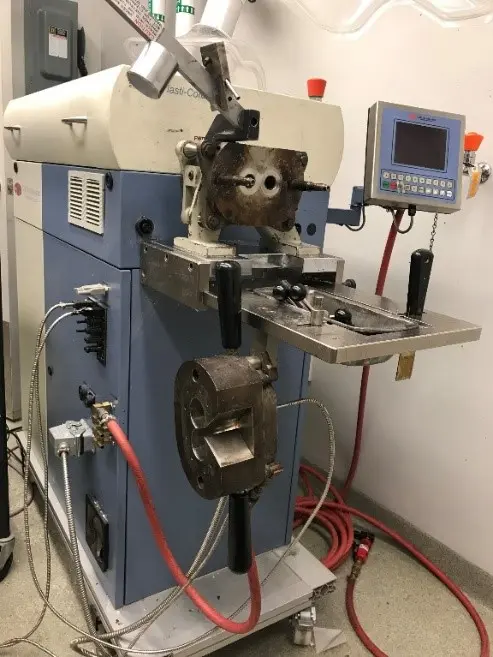

The Thermoset Elastomers Laboratory in the Saab Emerging Technologies and Innovation Center (ETIC), Rooms 125B-125D, was partially sponsored by Freudenberg-NOK, a supplier of automotive components. The capabilities were expanded by a generous equipment donations from the New England Plastics and Rubber Group (NERPG), Draka Cableteq, C.W. Brabender, and Alpha Technologies. The laboratory and other facilities contain equipment for mixing, forming, and characterization of thermoset elastomers.