Inventions Will Improve Biomedical Imaging, Plastics Manufacturing and Battery Storage

Image by Edwin L. Aguirre

Image by Edwin L. Aguirre

Cecil Joseph, shown here at the Biomedical Terahertz Technology Center, is co-developing with Prof. Robert Giles a high-speed terahertz imaging system.

05/18/2017

By Edwin L. Aguirre

The UMass President’s Office recently awarded a total of $75,000 to three teams of UMass Lowell faculty researchers to develop new technologies aimed at detecting cancer, improving the cost and quality of plastic products and creating highly stable battery power supplies. The seed funding through the Technology Development Fund will help bring the research projects a step closer to market.

Physics Prof. Robert Giles and Cecil Joseph of the university’s Biomedical Terahertz Technology Center (BTTC) are designing and building a new high-speed imaging system—a grating-based terahertz spectrometer—for cancer diagnosis, remote sensing and security screening, while Prof. David Kazmer of the Department of Plastics Engineering has designed a new extrusion screw for improving product consistency and energy efficiency in plastics manufacturing. Asst. Prof. Ertan Agar of the Department of Mechanical Engineering is collaborating with Asst. Prof. Patrick Cappillino of UMass Dartmouth to develop new bio-based battery chemicals that can help power not only a home but also an entire city grid.

Other recipients of this year’s funding include five faculty teams from the UMass campuses in Boston, Amherst and Worcester.

“With these technology development awards, we are recognizing innovation across our five campuses and investing in discoveries with the potential to contribute to the economy and change lives,” UMass President Marty Meehan said. “These awards highlight faculty excellence and underscore the role of a public research university to advance knowledge and spur entrepreneurship and economic development.”

From Cancer to Explosives

Unlike X-rays, terahertz radiation has no harmful side effects on humans, according to Joseph, who is the BTTC program manager. “It offers high resolution and intrinsic contrast, that is, contrast without the need to add external chemical agents when imaging tissues,” he says.

Biomedical applications of terahertz imaging include screening for cancers of the skin, colon and breast; tracking the concentration of nanoparticles used in patients to diagnose and treat malignant tumors; and assessing the severity of burn wounds. In the pharmaceutical industry, the technique can be used to evaluate the thickness and uniformity of pill coatings.

Joseph says terahertz imaging can also improve homeland-security screening.

Image by Biomedical Terahertz Technology Center

Image by Biomedical Terahertz Technology Center

Current commercially available terahertz imaging systems have long delays in acquiring the terahertz signal, which can take up to 15 minutes or more for an image. This is limiting widespread adoption of the technology, Joseph says.

“Our proposed invention incorporates an optical component, called a grating, into the existing system that will enable the user to acquire the signal instantaneously, thus making the system suitable for real-time imaging,” he adds.

A High-efficiency Screw

Plastics extrusion is a high-volume manufacturing process in which raw plastic material is continuously fed and melted in the extruder machine. The machine’s turning screw forces the molten plastic into a die, which shapes the plastic into a variety of products, ranging from pipes and tubing to plastic films, sheeting and wire insulation.

Image by Edwin L. Aguirre

Image by Edwin L. Aguirre

Prof. David Kazmer’s new stainless steel plastics extrusion screw measures 3.5 feet long and 1.5 inches in diameter.

Unlike a conventional screw design, in which the resin pellets melt slowly in the screw’s deep and widely spaced channels, the screw that Kazmer and his graduate student, Clemens Grosskopf, have developed, called a “fractal screw,” divides the melt into narrow channels, cutting and mixing the materials for increased throughput and consistency.

Kazmer will use the funding to evaluate the technical and commercial feasibility of the new screw design. If successful, the technology will be licensed to companies to generate income for the university.

Developing a Mushroom-based Battery Electrolyte

A new class of batteries, called non-aqueous redox flow batteries (NRFBs), has recently attracted attention because of their high storage capacity and energy output. However, the poor stability of their electrolyte—the chemical solution that allows the flow of electrical charge between the batteries’ positive and negative terminals—combined with their relatively short life cycles, are hindering their widespread use as a renewable energy source.

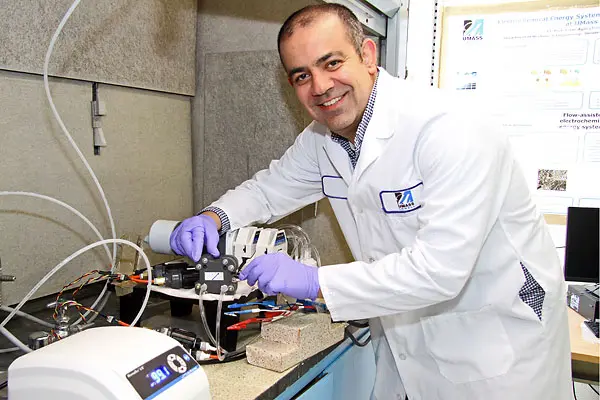

Image by Edwin L. Aguirre

Image by Edwin L. Aguirre

“The technology can be commercialized to provide small- and large-scale energy storage solutions for residential homes and city power grids,” says Agar. “This will enable widespread implementation of intermittent energy sources, such as wind and solar, and help reduce greenhouse gas emissions from burning fossil fuels. It will also increase the reliability of the country’s grid system and improve the security of our energy supply.”

Assisting Agar in the project is Mahnaz Nourani, a first-year Ph.D. student in mechanical engineering.