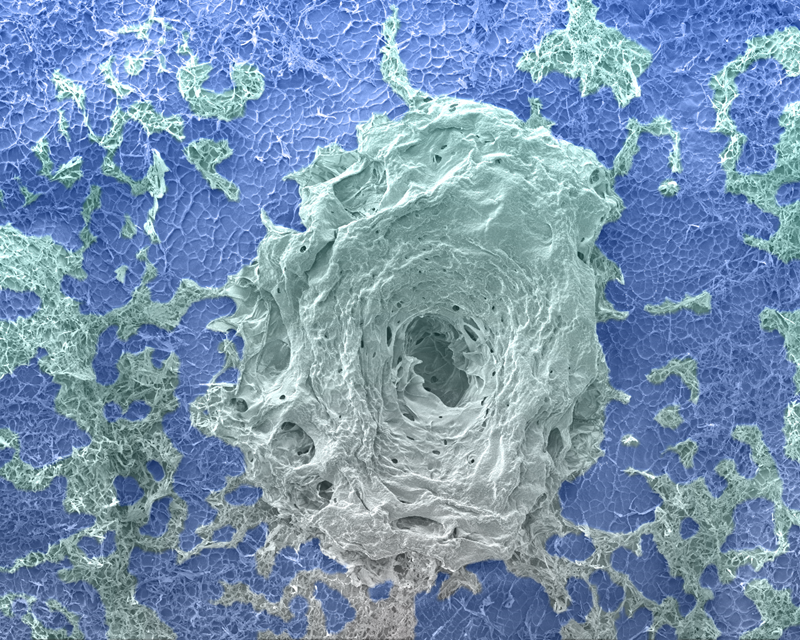

First Place: Eye of the Hurricane: A Hidden Calm in a Tissue Scaffold

By Mert Gezek

This scanning electron microscope (SEM) image, captured at 140× magnification with an accelerating voltage of 5 kV, reveals a striking "eye of the hurricane"-like structure that naturally formed within a tissue engineering scaffold. The scaffold is composed of gelatin methacryloyl (GelMA) and calcium peroxide particles, designed to enhance tissue regeneration through controlled oxygen release. This particular region showcases how material behavior during fabrication can give rise to unexpected yet visually captivating microarchitectures. It serves as a reminder that even in engineered environments, nature’s patterns and beauty can spontaneously emerge.

UML Department or Company Name: Biomedical Engineering and Biotechnology Doctoral Program

Electron microscope used: Field-emission Scanning Electron Microscope (FE-SEM) JEOL JSM 7401F

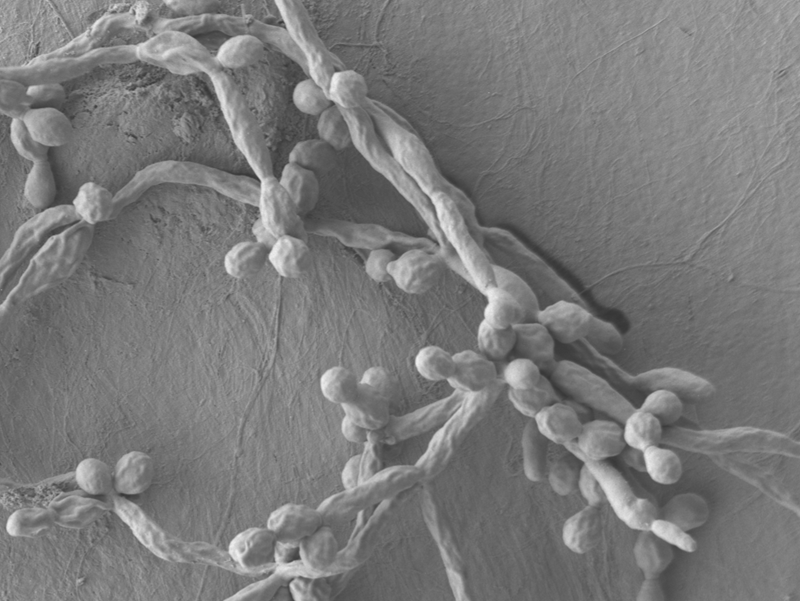

Second Place: Biofilm growth

By Majid Akbar

Images were taken for the pretreated healthy biofilm of fungus candida albicans on denture materials by SEM in SEM mode at 1500x magnification and the purpose was to show how pretreated fully grown biofilm looks like and how it will look once it is treated with minimum inhibitory concentration of antifungal drug.

UML Department or Company Name: Chemistry Department

Electron microscope used: JEOL JSM 7401F Unit 2

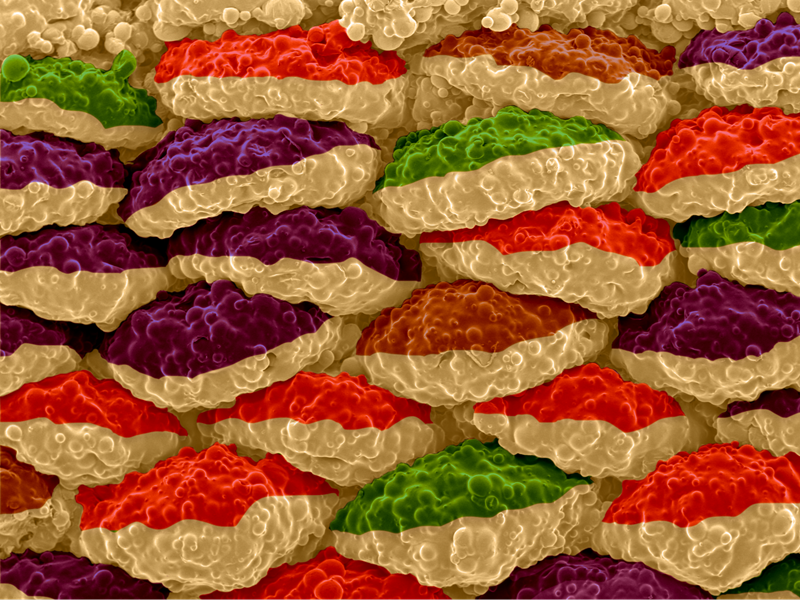

Third Place: Foamonut

By Nariman Rajabifar

Controlling porosity in thermoplastics is a challenge, mainly on account of multiple variables and the nature of foaming methods. However, recent advancements have conduced to fabricating foams with a precise control over poros content. This image shows a 3D printed foam using FDM technique, where the printed object has turned into foam, from a solid feedstock, due to the applied heat. This image was captured on a JEOL JSM 6390 instrument. The significance of this image is the orientation of paths on top of each other in an interesting way. In particular, 3D printing has enabled architecting the printed paths in a fairly symmetric order. Because we controlled the porosity inside each path, the surface (i.e., exterior of the paths) exhibits a blown, ovoid design resemblance to donut, which is why we called it "Foamonut".

UML Department or Company Name: Polymer/Plastics Engineering

Electron microscope used: JEOL JSM 6390

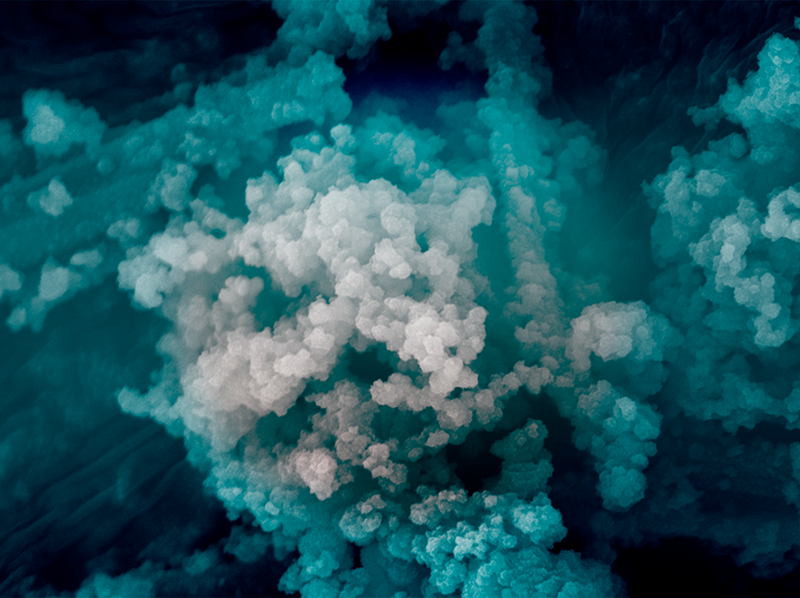

Fourth Place: Layers of change

By Ioana Knopf

The goal of the project was to generate a carbon-negative version of calcium carbonate by mineralizing carbon dioxide. The morphology of the resulting carbonate was studied by SEM, which was typically found to be rhombohedral calcite. In this instance, processing conditions were changed and the calcite was altered into these unusual layered structures, probably obtained through recrystallization. Some of the original rhombohedral crystals are still present in the sample, providing an interesting juxtaposition.

UML Department or Company Name: Arrakis Materials Inc.

Electron microscope used: JEOL JSM 7401F

Fifth Place: Depths Unseen: Pores of Perception

By Mubarak Ayinla

This SEM image captures the mesoporous beauty of UML-COF3, a covalent organic framework (COF) synthesized from an aldehyde and amine. From a shallow cyan to abyssal teal, I have rendered a gradient inspired by oceanic blues; the image mirrors the layered mysteries of nature, from sea to sky. But unlike the ocean, where depth centers around the trench, this framework reveals its most profound intricacies at the margins. In COFs, the true power often lies in the less apparent: nanoscale pores, hidden linkages, and the unseen architecture that governs function. Much like life’s formative experiences, it is the smallest, most dispersed elements that define the material's capacity; whether for gas capture, molecular separation, or ionic conduction. The edge intensity of this image reminds us that scientific depth often exists where we least expect it, at the periphery of perception yet central to performance.

UML Department or Company Name: Chemistry

Electron microscope used: JEOL JSM 7401F