Image by Brooke Coupal

Image by Brooke Coupal

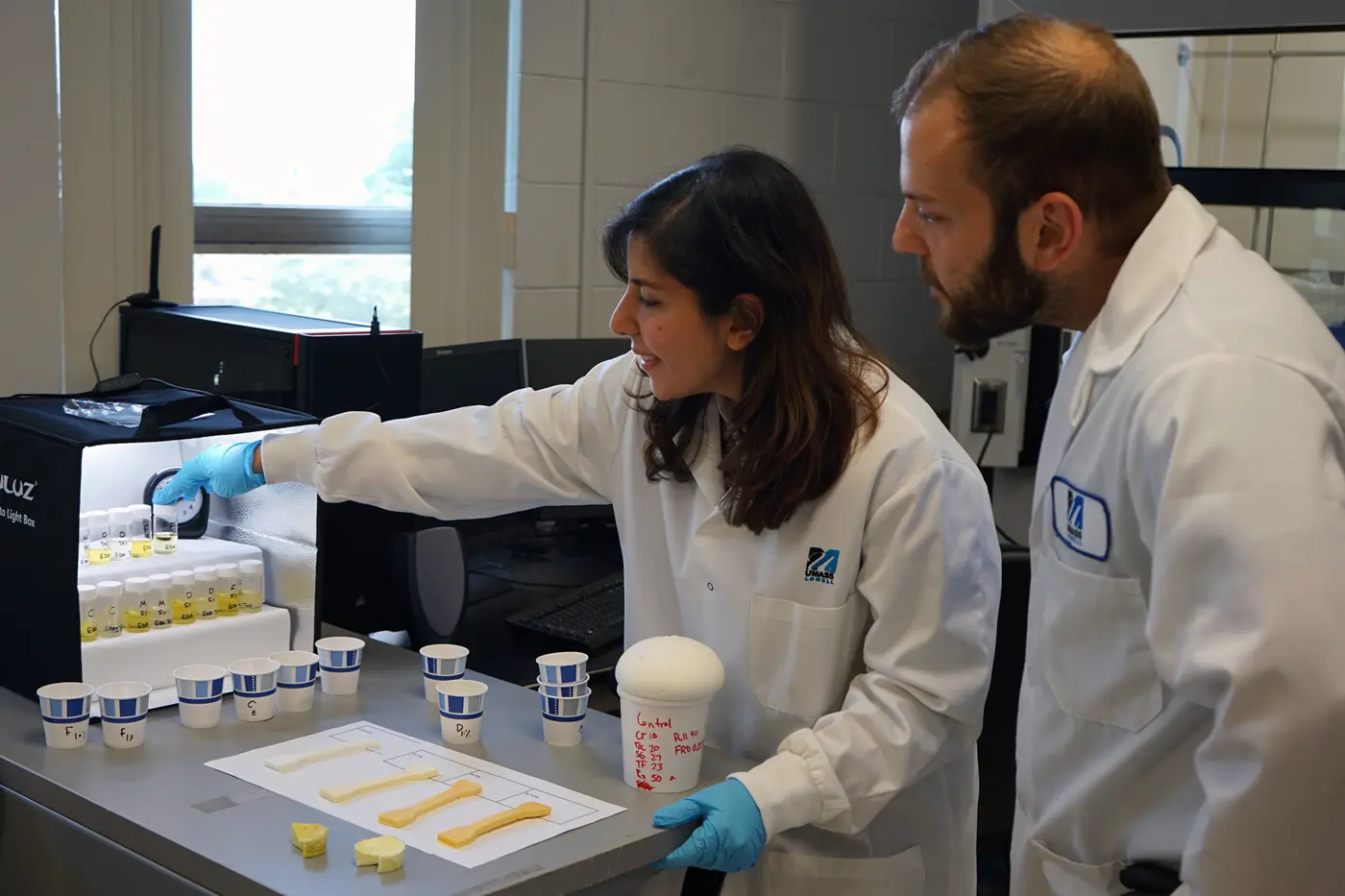

Ph.D. student Shayesteh Tafazoli and Chemistry Asst. Prof. James Reuther analyze the breakdown of polyurethane.

As soldiers spend long days on their feet, an important part of their uniform can quickly wear down – their combat boots.

Chemistry Asst. Prof. James Reuther and his lab group are developing a way to keep combat boots in commission longer. Their research is being funded by Harnessing Emerging Research Opportunities to Empower Soldiers (HEROES), a joint research and development initiative of UMass Lowell and the United States Army Combat Capabilities Development Command Soldier Center. HEROES awarded Reuther and industry partners two grants totaling more than $1.1 million for their work, with roughly $265,000 going to UMass Lowell.

“Our research is specifically being applied to combat boots, but because of the way we designed this chemistry, it can be broadly applied to all footwear and beyond,” Reuther says.

The bottoms of combat boots, known as the outsole, are traditionally made of rubber. In collaboration with Maine-based Polymer Laboratory Solutions and Germany-based BASF, Reuther is looking to replace rubber outsoles with polyurethane, a synthetic resin that is lighter than rubber and easier to break in, making the boots more comfortable.

Reuther and his lab group created dynamic chemical bonds that they incorporated into polyurethane to provide a self-healing property to boot outsoles, in which a tear would mend itself.

“That’s our secret sauce,” Reuther says. “Because of this dynamic bond exchange, the outsole can heal itself spontaneously when we apply heat or pressure.”

Image by Brooke Coupal

Image by Brooke Coupal

A piece of self-healing polyurethane.

With a polyurethane formula supplied by BASF, Reuther’s research team has successfully tested their dynamic chemical bonds in the lab. Reuther and polymer science Ph.D. student Shayesteh Tafazoli also traveled to Polymer Laboratory Solutions in Lewiston, Maine, to generate an outsole using self-healing polyurethane.

“We are working directly with commercial resin and not just on an experimental scale, which is very nice,” says Tafazol.

Partnering with Acton, Massachusetts-based Haartz Corp., Reuther intends to incorporate the same self-healing property into synthetic leather. They envision this leather replacing cowhide leather in the upper part of combat boots, such as in the tongue. As with polyurethane, synthetic leather is lightweight compared to cowhide and easier to break in.

When soldiers are ready to retire their self-healing combat boots, Reuther has a way to keep them out of landfills. By integrating a specific chemical bond, the researchers can break down the material into byproducts that can be upcycled into other products, such as medical devices.

With the wide uses of polyurethanes (from sofas to insulation) and synthetic leathers (from handbags to automotive interiors), Reuther feels the possibilities are endless for how the research can be applied.

“Our goal is that you can introduce these chemical bonds to applications that pose the biggest sustainability problems, preventing them from entering landfills,” he says. “We’re seeing how commercially viable this could be.”