Project Is Supported by $500K Grant from the State

As world demand continues to grow, the global market for printed circuit boards, or PCBs, is expected to hit nearly $141 billion by 2032, according to a business report.

02/02/2024

By Edwin L. Aguirre

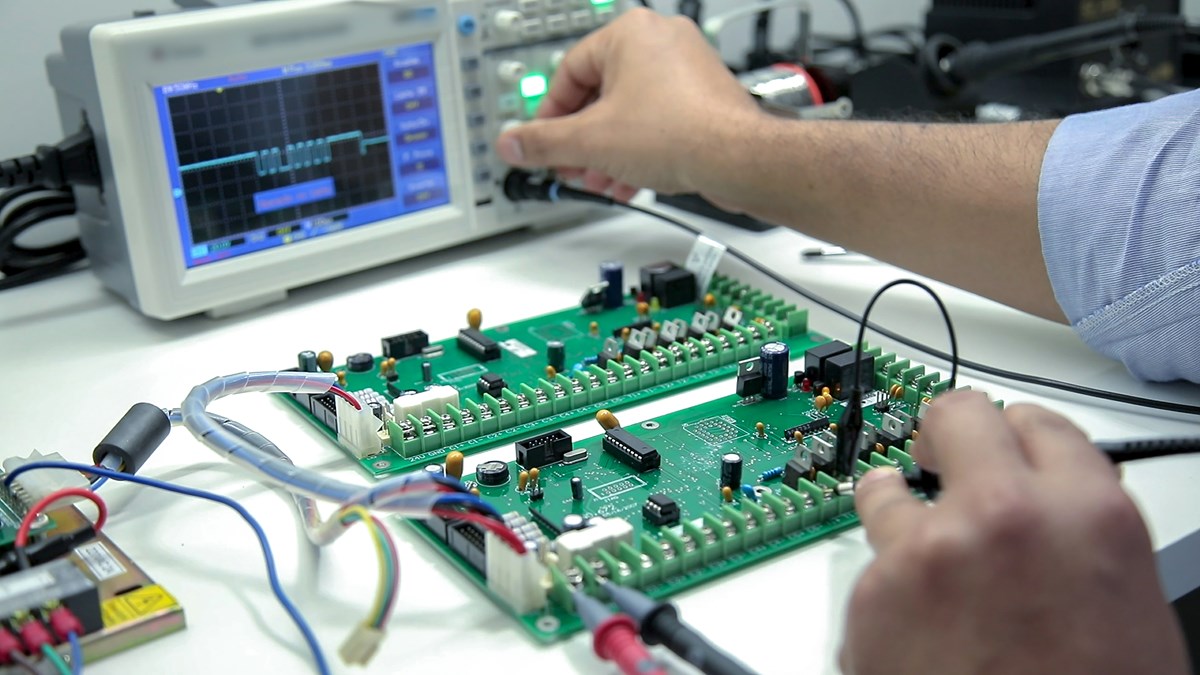

Consumer electronics that we use daily – smartphones, computers, televisions, home appliances and medical devices, as well as electronics in cars – all require printed circuit boards, or PCBs, to function.

These non-conductive boards are printed or etched with copper lines for mounting and connecting electronic components together to form a working circuit or assembly. As world demand continues to grow, the global market for PCBs reached $86.18 billion in 2023, and is expected to hit nearly $141 billion by 2032, according to Precedence Research.

To help train students and industry workers in the design and fabrication of PCBs, UMass Lowell is establishing the Massachusetts Electronics Manufacturing Evolution (MEME) Laboratory on North Campus. The project is supported with a $500,000 Massachusetts Skills Capital Grant for purchasing equipment for the facility. The grant program is offered by the Massachusetts Workforce Skills Cabinet and funded by the state through its capital budget.

Engineering Dean and Mechanical Engineering Prof. James Sherwood is the project’s principal investigator (PI), with Bradley Mingels, director of workforce development for professional and undergraduate education at the Francis College of Engineering, as co-PI.

UMass Lowell’s planned Massachusetts Electronics Manufacturing Evolution (MEME) Laboratory on North Campus will help train students and industry workers in the design and fabrication of PCBs.

“Currently, there are more than 2,400 unfilled jobs in electronics manufacturing in Massachusetts,” says Mingels. “The MEME Lab will help address this critical and growing shortage of talent by developing a workforce skilled in electronics hardware preproduction, process development and inspection.”

The grant will fund the procurement of equipment for fabricating multilayered circuit boards, component pick-and-place equipment and solder reflow ovens for finishing boards. UML’s collaboration partners, which include LPKF, Nano Dimension and Essemtec, are also donating a portion of the equipment, together with associated software and technical support.

According to Mingels, PCB manufacturing was prevalent in the U.S. in the past, but most of it went offshore over the past two decades.

“This could be an opportunity to bring many jobs back onshore, especially for some of the more complex PCB designs, reducing our dependence on out-of-state and overseas fabricators,” he says.

Mingels says through the MEME Lab, UMass Lowell students will gain insights into how PCBs are made, their physical limitations and their performance.

“These insights are traditionally learned on the job,” he says. “By having these experiences as undergraduates, students can have a more immediate impact on their future organizations.”

Mingels says the goal is to create opportunities for electrical engineering majors to get experience with PCB design and for industrial engineering students to get exposure to PCB fabrication and process development.

“This is a new and novel approach,” he says. “Students will develop in-demand skills as well as a deeper understanding of the two sides of the PCB industry.”

In addition to engineering students, the program will target underemployed and underskilled workers in the region, as well as secondary and post-secondary students and trainees. It will also support regional commercial, defense and health care industries by offering them adaptable training programs, prototyping and rapid manufacturing tool-up capability, Mingels says.